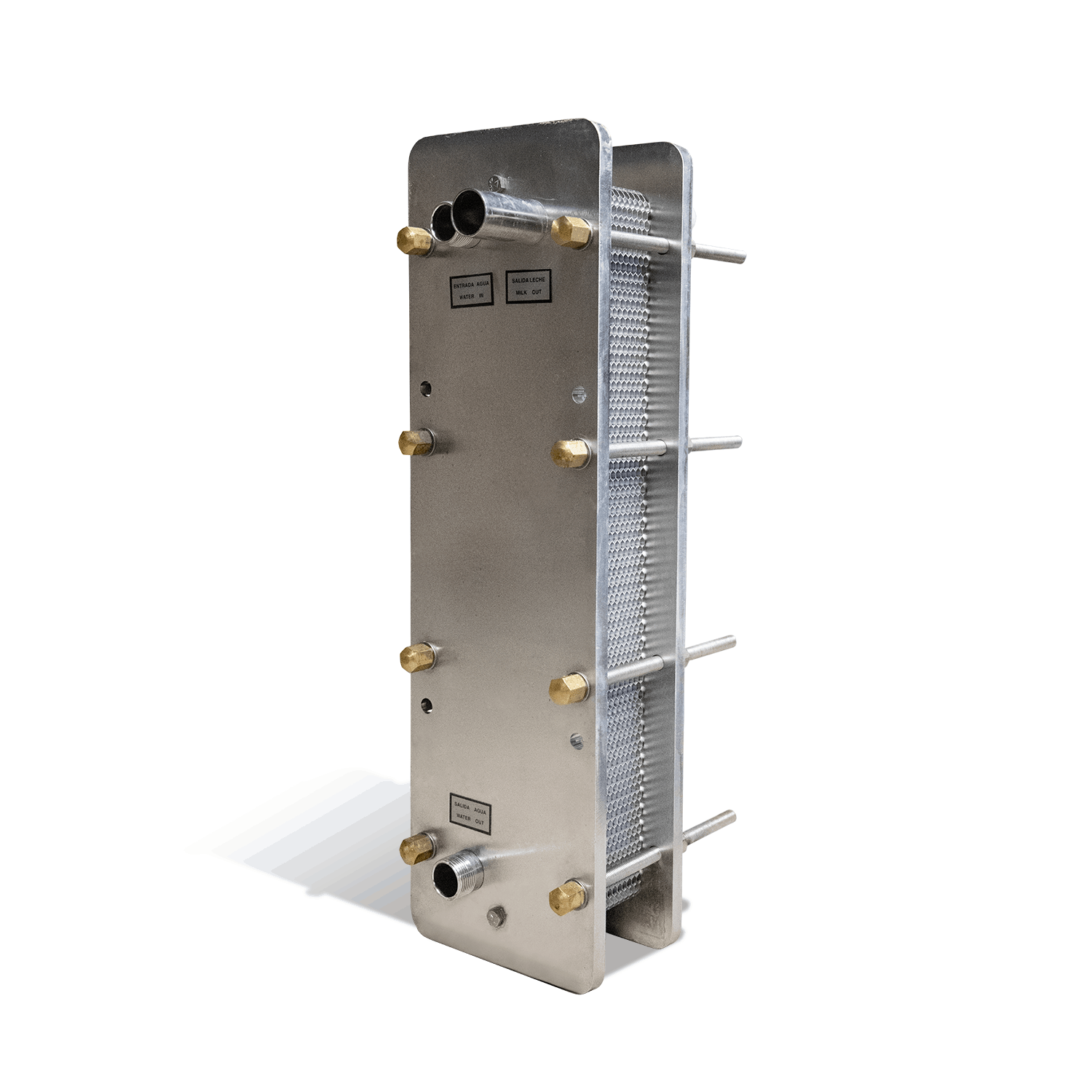

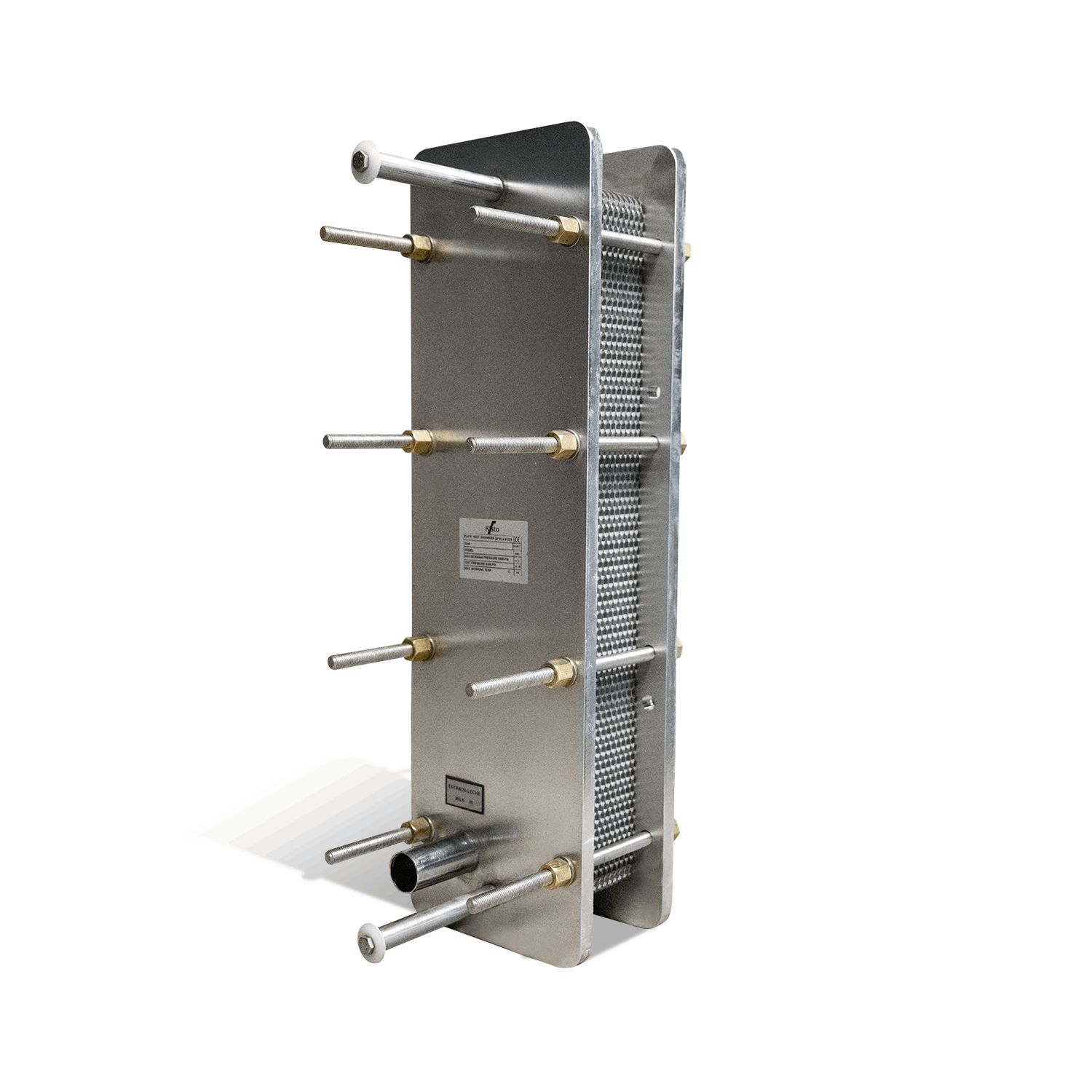

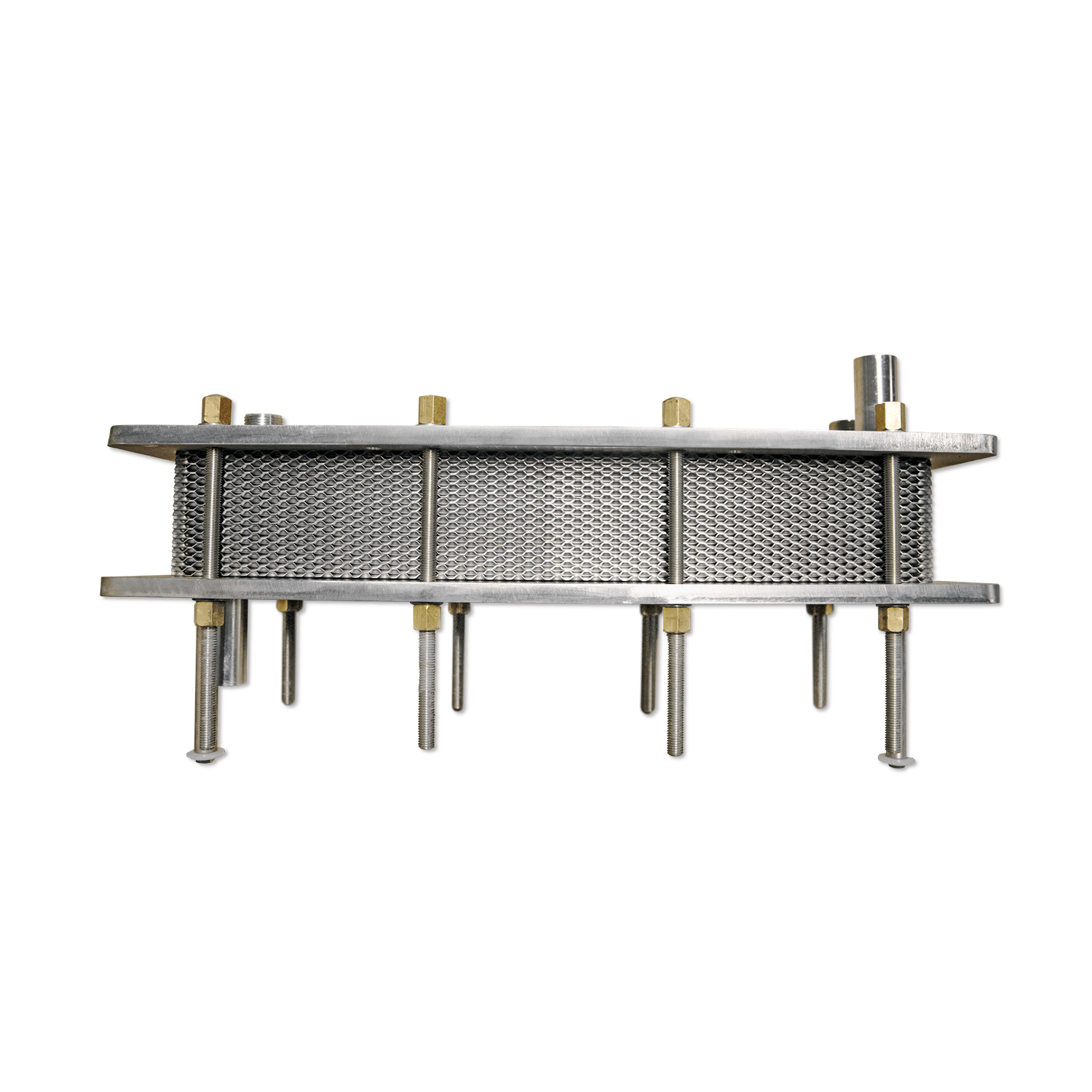

Plate cooler (plate heat exchanger, heat exchanger)

Pre-cooling for better milk quality and lower energy costs

- Number of plates: 27 – 55

- Milk flow: 1650 – 3650 Litres

- Water flow: 4850 – 7250 Litres

- Made entirely of stainless steel

- Hygienic

- Solid framework

- Solid mounting bracket

- Suitable for up to 4 bar

- Plates easily replaceable with no gluing required

- More hygienic than glued designs

- A standard in the dairy industry for many years now

- Special plate shape with a high turbulence effect

- Panel design in accordance with USA 3A sanitary standards

- Excellent cooling capacity due to highly efficient heat exchange

- Optimal plate cleaning

- Suitable for well water

- Any water which is also suitable as livestock drinking water

- can be used!

- 1″ water inlet / outlet thread

- 34 mm external milk inlet / outlet (smooth tube)

Rapid cooling of milk with the plate heat exchanger safeguards milk quality because the storage temperature can be reached sooner. Subsequently, the heat exchanger slows down the growth of bacteria in the milk. Pre-cooling the milk via a plate heat exchanger before it reaches the cooling tank also saves costs. The heat exchanger is supplied with well water or tap water. Both pre-cooling and storage cooling must operate efficiently to preserve milk quality. Pre-cooling with the plate heat exchanger depends on the water to milk flow ratio. Optimum pre-cooling is achieved using plate coolers with a ratio of approx. 2.5: 1.

Pre-cooling the milk using the plate heat exchanger saves energy during subsequent cooling in the cooling tank as the milk enters the cooling tank at a lower temperature. You can save up to 60 percent on your milk cooling energy costs with a well-dimensioned plate cooler from Risto. Risto offers several plate coolers to provide the optimum solution for each application: Plate coolers in six different sizes. Depending on how much you want to invest, you can even choose a highly efficient cooler with 55 plates featuring a stainless steel frame.

Plate cooler (plate heat exchanger, heat exchanger)

Fresh milk is exposed to germs immediately after milking. In the plate cooler (plate heat exchanger or heat exchanger) from Risto, the milk is quickly cooled down. Germs can rarely develop here. However, apart from hygiene purposes, the pre-cooling also saves energy costs. When flowing into the cooling, the milk is already cooled down to 14 – 20°C (depending on the water temperature) and thus will be cooled much more quickly to the end desired temperature. Tap water or well water available at the farm is used as a cooling medium. The manufacturer recommends a 2.5: 1 ratio of milk to water. Mixing of milk and cooling water in the RISTO plate cooler (plate heat exchangers, heat exchanger) is absolutely excluded. For this purpose, reliably and thoroughly machined seals are installed between the device components. A stainless steel structure ensures a long life of the system. At the same time, the plate cooler (plate heat exchanger, heat exchanger) can withstand pressures of up to 4 bars and can be easily retrofitted with spare parts for the plates. A true cost saving factor is the ability to use any kind of well water for the precooling, which your cattle can drink without any problems.

Price list

| Amount Plates | Milk flow L/h | Water flow L/h | Price in Euro |

| 27 | 1650 | 4850 | 1.150,- |

| 31 | 1900 | 5450 | 1.220,- |

| 37 | 2350 | 5850 | 1.320,- |

| 43 | 2750 | 6450 | 1.420,- |

| 49 | 3250 | 6950 | 1.530,- |

| 55 | 3650 | 7250 | 1.630,- |

All prices excl. VAT